Sintered NdFeB magnets are the most widely used type of rare earth permanent magnets today, thanks to their exceptional magnetic properties, including high remanence, strong coercivity, and outstanding energy product. At GESmaterials, we specialize in supplying high-performance sintered NdFeB magnets for industries ranging from automotive and electronics to renewable energy and advanced manufacturing.

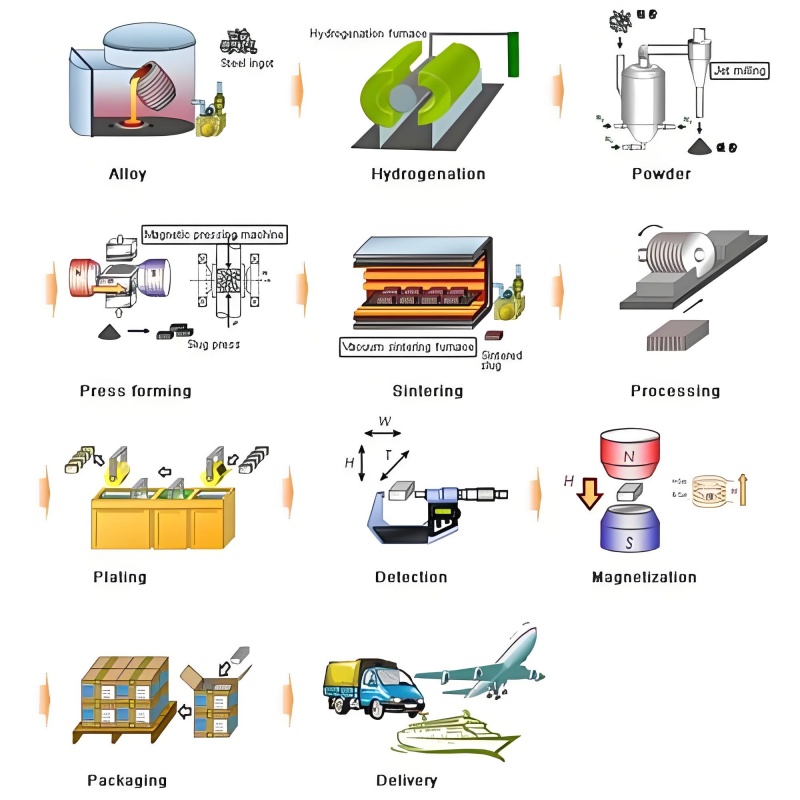

To help our customers better understand the technology behind these powerful magnets, let’s walk through the key steps of the production process:

1. Alloy Melting

The primary raw materials for NdFeB magnets include rare earth metals, iron, ferroboron, and trace amounts of other elements. In a vacuum environment, these materials are melted and cast into alloy ingots or thin flakes, ensuring chemical uniformity and high purity.

2. Hydrogen Decrepitation (HD)

Using the principle of rare earth metals absorbing hydrogen and expanding, the alloy flakes are broken down into coarse NdFeB powder at the millimeter scale. This powder is then stored in sealed containers to prevent oxidation.

3. Jet Milling

The coarse powder is further refined through high-pressure jet milling, where particles collide and fracture into micron-sized NdFeB fine powder. These fine powders are highly sensitive to oxygen and are stored under inert conditions.

4. Molding & Magnetic Orientation

Under a nitrogen-protected atmosphere, the NdFeB fine powder is loaded into forming molds. By applying a strong magnetic field during pressing, the powder particles are aligned to produce anisotropic NdFeB green compacts. Different mold designs allow for a wide range of shapes and sizes.

5. Sintering & Annealing

The green compacts are vacuum-sintered and heat-treated (annealed) to improve density, strength, remanence, and coercivity. At GESmaterials, we operate advanced multi-chamber continuous vacuum sintering furnaces to achieve consistent quality and high performance.

6. Precision Machining

The sintered blocks are machined into semi-finished magnets using processes such as centerless grinding, double-face grinding, wire-cutting, slicing, drilling, and arc-cutting. The final geometries include blocks, discs, rings, arcs, and customized irregular shapes.

7. Grain Boundary Diffusion (GBD)

By introducing specific elements into the grain boundaries during sintering and aging, the microstructure of the magnet is optimized. This process enhances performance while minimizing the need for heavy rare earth elements, reducing cost and improving sustainability.

8. Surface Treatment

To ensure long-term stability and corrosion resistance, NdFeB magnets undergo surface protection. Our factory operates fully automated coating lines, offering passivation, zinc plating, nickel plating, copper plating, epoxy electrophoresis, vacuum aluminum coating, and zinc-aluminum spraying—meeting the requirements of different application environments.

9. Quality Inspection

Comprehensive testing is carried out to evaluate magnetic properties, service performance, and elemental composition. Automated inspection equipment ensures both high efficiency and accuracy, providing customers with reliable quality assurance.

10. Magnetization

The finished magnets are magnetized by applying a short, intense pulse of current through a coil, generating a strong magnetic field. Depending on application requirements, we provide different magnetization orientations such as through-thickness, radial, and multi-pole magnetization.

11. Packaging & Shipment

Finally, the magnets are packaged according to customer specifications and international transport standards to ensure safe delivery by air, sea, or land to destinations worldwide.

Conclusion

From alloy melting to final packaging, the production of sintered NdFeB magnets involves a highly precise and controlled series of steps. At GESmaterials, we combine advanced technology with strict quality standards to deliver magnets that meet the demanding requirements of automotive, electronics, renewable energy, and industrial applications.

If you’re looking for a reliable supplier of sintered NdFeB magnets with consistent quality and flexible customization options, contact GESmaterials today—your trusted partner in magnetic solutions.